What Is a Hydraulic Actuator?

Hydraulic actuators are cylindrical tube and piston assemblies that utilize hydraulic power to generate linear, rotary, or oscillatory motion. This movement, in turn, is used to operate various mechanical tools and systems, such as balers, cranes, excavators, loaders, and presses. Compared to pneumatic or electrical actuators, these devices offer several advantages with regard to power, versatility, and affordability.

The following article provides an overview of hydraulic actuators, outlining the types available, comparison to pneumatic and electric actuators, and the new technology available at Maverick.

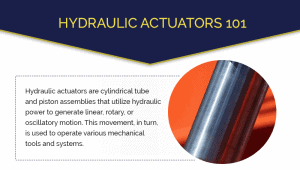

Types of Hydraulic Actuators

All hydraulic actuators rely on the principle of fluid compression to operate. However, they can be classified into single-acting or double-acting units. Single-action units apply pressure to only one side of the piston. As a result, a spring or gravity is required to provide the piston with a return stroke. These are sometimes called displacement cylinders. Double-acting units apply pressure on both sides of the piston. The difference in pressure between the two sides determines to which side the piston moves.

Some of the other classifications of hydraulic actuators include:

- Linear actuators: These actuators are used where linear motion is required.

- Rotary actuators: These actuators are used where rotary motion is required.

- Telescopic actuators: These actuators are used for applications requiring long strokes but small retracted cylinder lengths.

There are also several design and construction options available for the various actuator components. For example:

- The barrel can be made from a variety of materials (e.g., aluminum, cast iron, low-carbon mild steel, or stainless steel) with different finishes.

- The end caps can be welded on or fitted with threaded, tie rod, or flanged connections.

- The piston can be constructed from aluminum, brass, bronze, cast iron, or steel.

- The piston rod can be made to 4:3, 7:6, or 2:1 ratios.

- The cylinder cushioning can be installed at either or both sides of the cylinder.

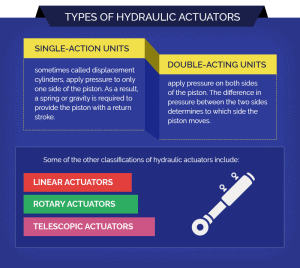

Hydraulic vs. Pneumatic vs. Electrical Actuators

Actuators are available in three broad categories: hydraulic actuators, pneumatic actuators, and electrical actuators. As indicated above, hydraulic actuators rely on the pressurization of hydraulic fluid to function. Similarly, pneumatic actuators utilize pneumatic pressure, while electric actuators employ electrical power to drive the cylinder and piston assembly.

Compared to the other two types of actuators, hydraulic actuators offer a number of advantages. They generate greater force (up to 25 times greater) and offer higher horsepower-to-weight ratios than pneumatic actuators. They have broader versatility and lower purchasing costs than electric actuators.

New Innovations in Hydraulic Cushioning Technology

One of the key components of a hydraulic actuator is the cushioning. It decreases the velocity of the piston as it approached the end cap, reducing the amount of stress placed on the cylinder components and the amount of vibrations transmitted to the rest of the system.

A new method of implementing hydraulic cushioning within the cylinder involves building it into the piston. As the piston approached the end of its stroke, a ring around its front edges forms a seal to close the port and stop the flow of oil, slowing the speed of the cylinder. A small orifice in the face of the piston allows for the controlled escape of the remaining hydraulic fluid trapped behind the piston until the end of the stroke. A larger path in the piston allows for full flow of the hydraulic fluid in a single direction as the piston makes its return stroke.

Some of the benefits of using this cushioning technology include:

- Smaller cylinder footprint compared to the conventional, externally mounted cushioning technology

- Faster actuation since the cylinder moves at normal speeds during the start of a stroke

- Smaller risk of operators overriding it as it cannot be seen

Contact the Hydraulic Cylinder Experts at Maverick Today

At Maverick Machine & Hydraulics, we specialize in hydraulic cylinders and products. If you need powerful hydraulic actuators with the latest cushioning technology, we’re here to help, providing cutting-edge solutions for your hydraulic cylinder manufacturing needs. To find out more about our products or discuss your application requirements with one of our experts, contact us today.