A Blast from the Past!

It is pretty hard to romance hydraulic cylinders but there are times when we think they are beautiful. Check out these photos and we think you will agree!

Here is the process we went through recently to thermally bind the bronze “wear layer” into the inner diameter of these pancake hydraulic cylinders. First, we rough machined the gland until it was undersize by 0.09”.

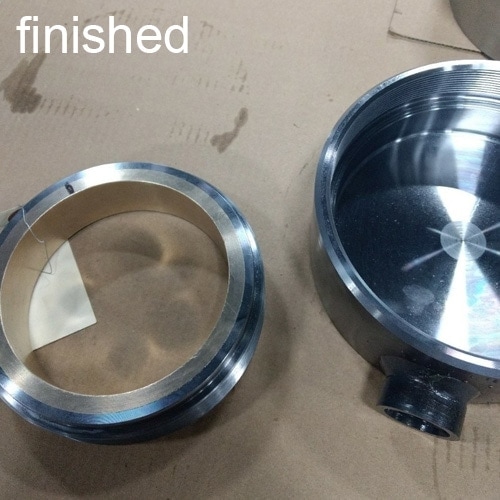

Next, we had the bronze material blast-welded onto the inner diameter while it was spinning! This is a very noisy and hot step and created the dusty, rough finish shown. Then we took the glands back to the lathe where we machined the seal grooves and threads. Check out the two-tone shiny metal surfaces in the finished gland photo! Finally, we assembled the rod and piston assembly into it and tightened it into the Hydraulic cylinder. What a beauty!

This style of hydraulic cylinder was used decades ago before glass filled nylons and thermally modified polymers with lubricating properties were readily available. Now they still find limited use in applications where the length of stroke doesn’t allow room to insert a separate wear band. For the record, this hydraulic cylinder has a stroke of only 10 millimetres, showcasing the evolution in hydraulic cylinder manufacturing materials and design principles over time.