STAINLESS STEEL HYDRAULIC CYLINDERS

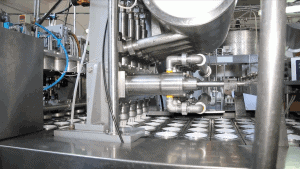

In the food and beverage industry, cleanliness is critical. As the products manufactured and processed are intended for consumption, companies within this industry must adhere to strict sanitation guidelines to ensure the health and well-being of their customers. These requirements and restrictions cover virtually every aspect of food and beverage processing operations, including how the equipment should be designed, constructed, installed, used, and serviced.

Cleaning is key to maintaining high hygiene levels in food and beverage processing facilities. However, as these operations often employ the use of harsh chemicals that corrode and otherwise damage sensitive equipment—such as mild steel cylinders—over time, it is essential to invest in equipment designed and built for durability even in harsh operating conditions.

For customers in the food and beverage industry, the team at Maverick Machine & Hydraulics offers stainless steel hydraulic cylinders. Compared to cylinders made from other materials (e.g., mild steel), they readily accommodate use in washdown-ready equipment to ensure processing facilities comply with industry standards without damaging their machines.

Properties and Benefits of Stainless Steel Hydraulic Cylinders

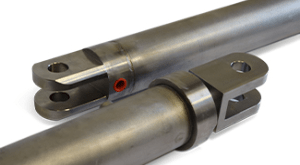

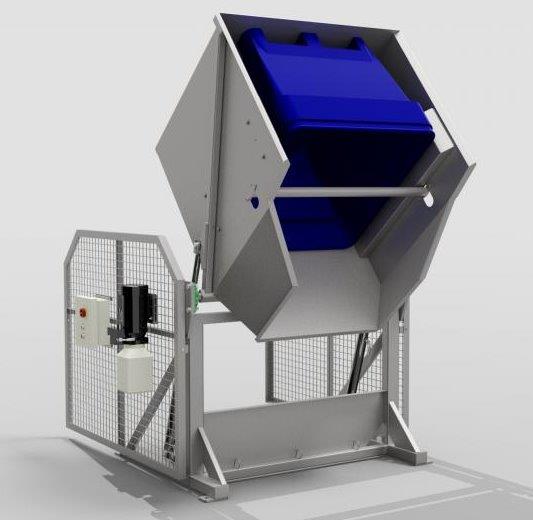

Hydraulic cylinders are found in a wide range of food and beverage processing equipment. Similar to all other machines and machine components within the industry, they must comply with various industry standards to ensure the integrity of products and safety of consumers. For this reason, industry professionals often employ stainless steel hydraulic cylinders, which demonstrate excellent strength and durability throughout their service lives. These qualities allow them to withstand the frequent cleaning operations needed to maintain sanitary processing conditions.

Stainless Steel Composition, Grades, and Benefits

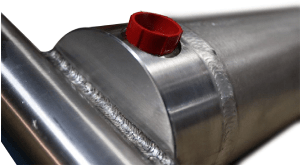

Stainless steel is an iron-alloy containing at least 10.5% chromium and varying levels of other alloying elements such as carbon, nitrogen, nickel, molybdenum, and manganese. It is available in several types and grades, such as 303, 304, 316, 17-4PH. While the exact composition of a particular stainless steel material influences the properties it demonstrates, all stainless steel has the following characteristics:

- High tensile and yield strength

- Excellent machinability

- Corrosion resistance

The latter quality stems from the presence of chromium—and, to a smaller extent, molybdenum—in the material. It is essential for equipment used in the food and beverage processing industry. Combined with the non-porous nature of stainless steel, it prevents contaminants (e.g., bacteria) from lingering on the surface of equipment, allowing machines to be cleaned more effectively and efficiently. It also ensures that components made from it—e.g., hydraulic cylinders—are long-lasting, resulting in lower equipment costs over time.

Industrial Applications of Stainless Steel Hydraulic Cylinders

Food & Beverage Industry

As indicated above, stainless steel hydraulic cylinders are widely used in the food and beverage processing industry for various pieces of equipment, such as cold press juicers and chocolate molding machines. Compared to the off-the-shelf products used in other industries, these components often feature different elements to meet higher sanitation standards. For example, they may have a more streamlined and solid design with a polished surface to minimize the number of spaces and surfaces where bacteria and other contaminants can accumulate.

Other Applications

Some of the other typical industrial applications for stainless steel hydraulic cylinders include:

- Coastal power generation plants

- Marine equipment

- Oil platform and pipeline risers

- Sewage and water treatment plants

- Ship heat exchangers

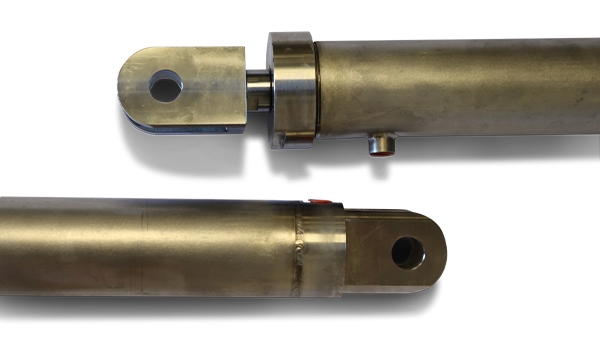

The durability of Stainless Steel is long proven. Typically the grades used in industry are 303/304/316/17-4PH which are mainly made up of a mixture of nickel, steel, and chromium which gives it excellent tensile and yield while still allowing machinability needed for production. This means a long and economic service life for your equipment.

But truly the prime feature of stainless steel hydraulic cylinders and tubes are their rust resistance and the cleanability that results from this. The secret to the corrosion resistance is in the chromium and molybdenum content which creates an oxide film on the surface of the metal. Because of this armour and the non-porous nature of the Stainless Steel germs can only linger is in the crevices and holes created during the machining process of the stainless cylinders. Our goal at Maverick is to minimize those places so the cleaning solutions can do their job effectively.

Maverick Machine & Hydraulics: The Stainless Steel Tube And Cylinder Experts

The team at Maverick Machine & Hydraulics fully understands how costly downtime can be to your bottom line. By partnering with us for your stainless steel cylinder needs, you benefit from our:

- Friendly and responsive customer service

- Precision cylinder machining services

- Unique numbering system that facilitates accountability and traceability

- 100% testing capabilities for manufactured and repaired components

- Full warranty programs, including a standard one-year replacement guarantee and optional five-year, pro-rated warranty

For additional information about our stainless steel hydraulic cylinder and tube offerings, contact us today.